As we celebrate Independence Day, we take great pride in being a manufacturing facility that produces American-made products.

King Plastic Corporation, founded in 1968, stands as the leading manufacturer of high-quality polymer sheets, slabs, and massive shapes, many of which were pioneered by our company. Our headquarters is a spacious 250,000 square-foot manufacturing facility located in North Port, Florida, with an additional distribution facility in Medford, Oregon.

So, this Independence Day and beyond, let’s make a commitment to support American-made brands. Explore their offerings, share their stories, and make a conscious decision to prioritize their products. Together, we can honor the legacy of these remarkable brands and ensure the continued success of American manufacturing.

Here are 20 American-made brands worth celebrating

King Starboard® – The Original Marine-Grade Polymer Sheet

King StarBoard® is the original marine-grade high-density polyethylene sheet and the leading brand in the marine industry. The King name is synonymous with quality to those who know plastics, and the King StarBoard® brand has been helping pros build better boats for more than thirty years.

King StarBoard® AS – The Anti-Skid Marine-Grade Polymer Sheet

King StarBoard® AS is an anti-skid, marine-grade, high-density polyethylene sheet. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King StarBoard® AS has a dot or diamond pattern on one side of the sheet and a matte finish on the other side. The special, high-friction anti-skid surface helps prevent slipping and promotes drainage.

King StarBoard® XL – The Lightweight Marine-Grade Cellular Sheet

King StarBoard® XL is a lightweight, marine-grade, cellular high-density polyethylene sheet that is up to 30% lighter than the original King StarBoard®. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King StarBoard® XL has a matte finish on both sides of the sheet.

King STARLITE® XL – The Lightweight Marine-Grade Cellular Utility Sheet

King StarLite® XL is an economical, cellular (closed cell), utility sheet made from select high-grade King StarBoard® recycled high-density polyethylene. The polymer is up to 35% lighter than the original King StarBoard®. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King StarLite® XL has a matte finish on both sides of the sheet.

King StarBoard® ST – The Polymer Building Sheet That Lasts a Lifetime

King StarBoard® ST is a unique and advanced, high-density polyethylene building sheet that lasts a lifetime. The polymer sheet is 25% stiffer than the original King StarBoard®. It is a product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King StarBoard® ST has a matte gloss finish on both sides of the sheet.

King StarBoard® WG – The All-Weather Wood Grain Polymer Sheet

King StarBoard® WG is a high-density polyethylene sheet with a wood grain finish. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King StarBoard® WG has a wood grain finish on both sides of the sheet.

King DuraStyle® – Custom Cabinet Door Program Made with King StarBoard® ST

King DuraStyle® Custom Cabinet Door Program combines King StarBoard® ST, the environmentally stabilized polymer building sheet, with designer styles and state-of-the-art CNC fabrication. The doors have a matte gloss finish and are developed to withstand the harshest outdoor conditions. They will not rust, delaminate or rot when exposed to UV, humidity or water. King DuraStyle® custom cabinet doors never need painting or refinishing. Ideal for outdoor areas where there may be water, high humidity and moisture.

King MediGrade® – The Antimicrobial Polymer Building Sheet for Healthcare Applications

King MediGrade® is a super tough, high-density polyethylene building sheet with an advanced antimicrobial technology for protecting the product surface against stain and odor causing bacteria, algae and fungi. Unlike surface antimicrobials, King Plastic’s advanced antimicrobial technology protects against bacterial degradation for the lifetime of the product. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King MediGrade® has a matte gloss finish on both sides of the sheet.

King ColorBoard® – The Colorful Environmentally Stabilized Polymer Sheet

King ColorBoard® is a colorful environmentally stabilized high-density polyethylene sheet. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King ColorBoard® has a matte finish on both sides of sheet. It is environmentally stabilized to withstand the harshest outdoor conditions. King ColorBoard® will not rust, delaminate or rot when exposed to UV, humidity or water.

King ColorCore® – The Multi-Color Engravable Polymer Sheet

King ColorCore® is a versatile multi-color engravable high-density polyethylene sheet with multiple layers of contrasting colors. It is a superior homogeneous sheet, a product of a unique state-of-the-art continuous process called Polyfusion, and manufactured to the highest standards in the industry. King ColorCore® has a matte finish on both sides of the sheet.

King CuttingBoard® – The Solid Polymer Sheet for Food Applications

King CuttingBoard® is a solid, high-density polyethylene sheet for food applications. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King CuttingBoard® has a natural matte finish on both sides of the sheet. The natural polyethylene color creates a clean and sanitary look that commercial food processing operations require. The non-porous surface does not absorb food odors and is easy to clean and sanitize.

King CuttingBoard® XL – The Lightweight Polymer Sheet for Food Applications

King CuttingBoard® XL is a lightweight high-density polyethylene sheet for food applications. The polymer sheet is up to 30% lighter than the solid King CuttingBoard®. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King CuttingBoard® XL has a natural matte finish on both sides of the sheet.

King CuttingColors® – The Solid, Color-Coded Polymer Sheet for Food Applications

King CuttingColors® is a solid color-coded high-density polyethylene sheet for food applications. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King CuttingColors® has a matte finish. It is available in five colors to help prevent cross-contamination among different food types and allergies – raw meat, fish, produce, poultry, and cooked meat.

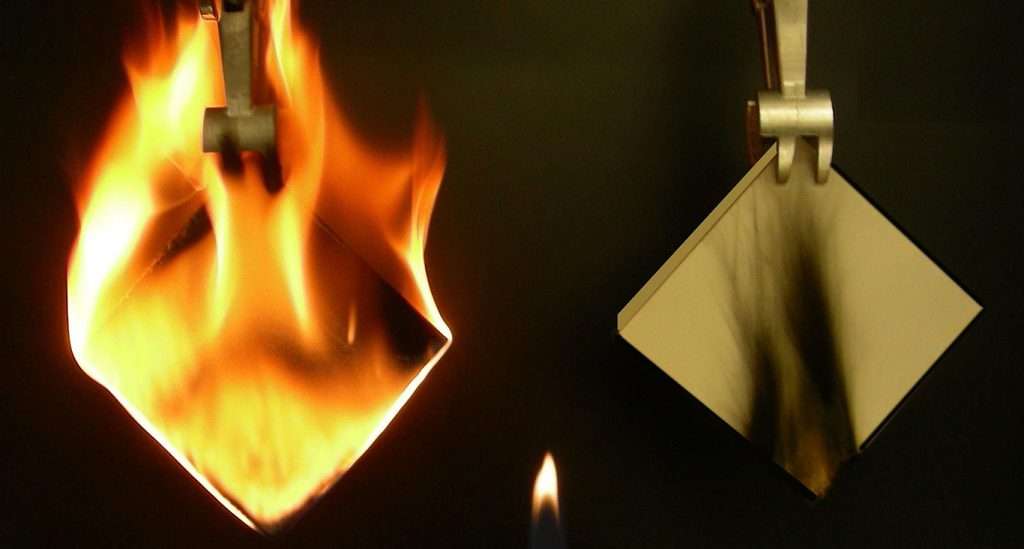

King Flameshield – Upgrade to King FlameShield ASTM E-84 Class A Flame Compliance and CAN/ULC-S102 for Canadian Compliance

King Plastic Corporation HDPE products with King FlameShield are improved in physical properties and cost effective compared to competing materials. We offer a Class A upgrade that improves the material’s overall physical properties to be more resistant to burning under flammable conditions.

King MicroShield® – Many of King Plastic Corporation’s Products Can be Upgraded to King MicroShield® with Advanced Antimicrobial Technology for Protecting The Product Surface Against Stain and Odor Causing Bacteria, Algae and Fungi

King MicroShield® polymer sheets use the latest technology for protecting the product surface against stain and odor causing bacteria, algae and fungi.

King PipeGrade® – The PE100 Special Black Polyethylene Sheet

King PipeGrade® is a PE100 special black polyethylene sheet. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency up to 1-1/2” thick. It is also available in compression mold greater than 1” through 4” thick, and extrusion mold from 2-1/2” up to 12” thick. Custom mold sizes available. King PipeGrade® has a smooth black finish on both sides of sheet.

King Plasti-Bal® – The Heavy Duty, Waterproof and Graffiti Resistant Polymer Sheet

King Plasti-Bal® is a custom high density polyethylene sheet designed for indoor commercial and industrial architectural applications. It will never warp, rot or delaminate when exposed to water and humidity. King Plasti-Bal® is durable, low maintenance and never needs painting or refinishing.

King Plasti-Shield® – The Borated Polyethylene Neutron Shielding Material

King Plasti-Shield® is a borated polyethylene neutron shielding material. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency of 1” thick. Custom sheets, blocks and slabs can be made as a special order in the compression mold or extrusion mold. King Plasti-Shield® has a smooth finish on both sides of the sheet. It is made with 5% boron by weight and our trademark purple color.

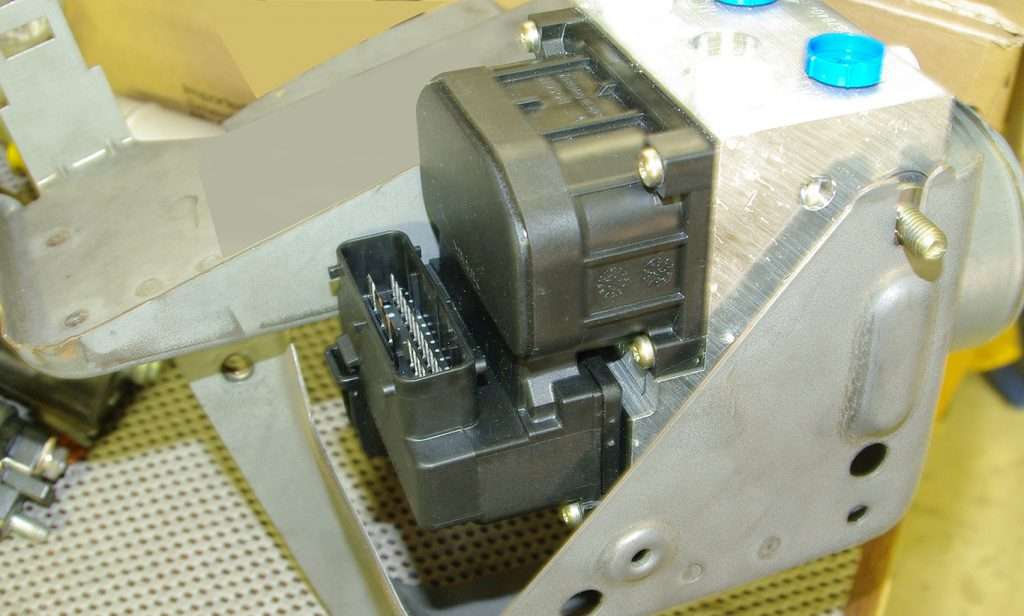

King KPC ABS – King Performance Commodity Acrylonitrile Butadiene Styrene

King KPC ABS is an Acrylonitrile Butadiene Styrene material known for its gloss surface, hardness, impact and heat resistance, toughness, and electrical insulation properties. It is manufactured in our state-of-the-art compression mold. King KPC ABS has a smooth gloss finish on both sides of the sheet. The advantage of King KPC ABS is the improved strength and rigidity of the acrylonitrile and styrene polymers with the toughness of the polybutadiene rubber.

King KPC ABS FR – King Performance Commodity Acrylonitrile Butadiene Styrene with Flame Retardant

King KPC ABS FR is an Acrylonitrile Butadiene Styrene material with Flame Retardant known for its gloss surface, hardness, impact and heat resistance, toughness, and electrical insulation properties. It is manufactured in our state-of-the-art compression mold. It has a smooth gloss finish on both sides of the sheet.

King KPC HDPE – King Performance Commodity High-Density Polyethylene

King KPC HDPE is a high-density polyethylene material. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency for gauges up to 1 -1/2” thick. Larger gauges are manufactured in our state-of-the-art compression mold or extrusion mold. King KPC HDPE has a natural, smooth gloss finish on both sides of the sheet.

King KPC LDPE – King Performance Commodity Low-Density Polyethylene

King KPC LDPE is a low-density polyethylene material. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency for gauges up to 1-1/2” thick. Larger gauges up to 4” thick are manufactured in our state-of-the-art compression mold or extrusion mold.

King KPC Polypro – King Performance Commodity Polypropylene

King KPC Polypropylene is a polymer material with excellent chemical, physical, and electrolytic properties. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency of up to 1” thick. Gauges greater than 1” are manufactured in our state-of-the-art compression mold.

King Hy-Pact® – The Super Tough Industrial Polymer Sheet

King Hy-Pact® is the super tough industrial polymer sheet that is environmentally stabilized with excellent physical properties. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process of quality sheets with tight tolerances and custom widths up to 60”. King Hy-Pact® has a clean white color with a smooth, non-skived finish on both sides of sheet for better material flow. It is also available in black.

Supporting American-Made Brands

As we reflect on Independence Day and the significance of American manufacturing, let us celebrate the incredible brands that embody the spirit of craftsmanship, innovation, and quality.

As consumers, we have the power to support and sustain American made brands by consciously choosing to purchase their products. By doing so, we not only invest in the exceptional quality they offer but also contribute to the growth of local economies and the preservation of American jobs.

Discover King Plastic career opportunities and learn more about Walk in Wednesdays.

Join us in celebrating these 20 American-made brands! Happy Independence Day, and let’s continue to support the heart and soul of American manufacturing!