DANIEL FINTON STAFF WRITER—YOURSUN.COM

Apr 6, 2024

Although Jeffrey King stands at 6-feet 5-inches tall, the shelves in his warehouse tower above him.

SUN PHOTO BY DANIEL FINTON

NORTH PORT — “Where do you want to move?” Jeffrey King’s father, Tom King, asked his family.

It was the 1960s, and the King family decided to move to the warmer climate of Florida. It would be much different from the likes of Ohio or Pennsylvania, where they had previously lived.

But one constant would remain: plastic.

In 1968, Tom King founded a plastics manufacturing plant in Venice.

In 2001, the company opened its new facility in North Port. Jeffrey King now owns and operates the company off Toledo Blade Boulevard, with some help from his family. His son, Charlie, helps oversee day-to-day operations.

The plant has around 200 employees and distributes its products around the globe. Some has even made it to the South Pole, used by the U.S. Navy.

You can find it at Bank of America Stadium in Charlotte, North Carolina, the home of the Carolina Panthers.

Condiment stands at the stadium are made with King Starboard, a marine-grade polymer sheet that’s commonly used for boats. Those sheets are upgraded with King FlameShield, a fire deterrent.

To get such products out, the North Port plant operates 24 hours per day to keep up with demand.

Shipments of small pellets come in from places such as Texas, Louisiana, Pennsylvania or Canada.

They’re sorted and stored in silos. Then they’re mixed and melted, converting them into usable sheets. Then they’re either stowed away in the warehouse as inventory, or loaded onto a truck and shipped to its next destination.

The only noise generated stays inside of its industrial walls. Only the hum of exhaust fans is heard outside.

Tractor trailers coming into, or leaving the facility make some noise too, but there are only around two to five that are stocked per day, King said.

Otherwise, the sounds of King, more or less, match the silence of the thick North Port brush surrounding most of the building.

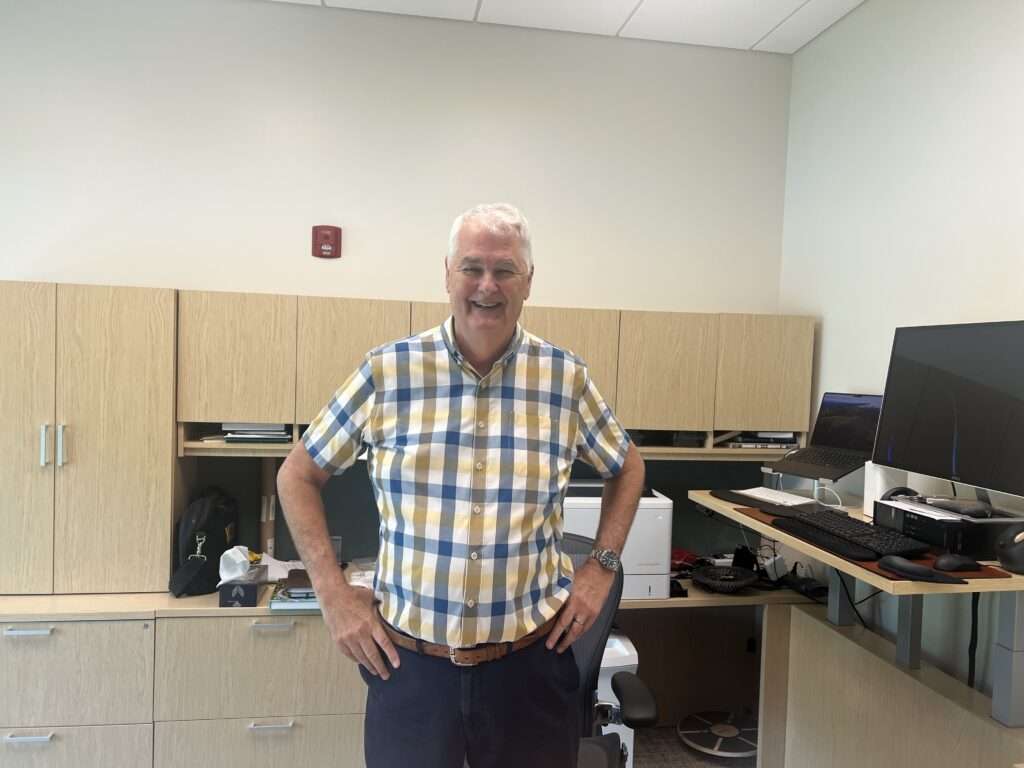

Jeffrey King is the president of King Plastic, a business that is home to 200 jobs in North Port.

SUN PHOTO BY DANIEL FINTON

Though it may not look like it from Toledo Blade Boulevard, King Plastic is a widespread center with hundreds of employees.

SUN PHOTO BY DANIEL FINTON

GETTING PAST COVID

During the pandemic in 2020, production at King persisted and people kept their jobs, King said. Jeffrey King is the president of King Plastic, a business that is home to 200 jobs in North Port. SUN PHOTO BY DANIEL FINTON

“COVID was certainly an interesting time. But we stayed open. We were essential, since we provide to the Navy and others,” he said.

While demand was not quite as high as it usually was prior to the pandemic, it was still there.

After the dust settled, everything was back to normal. For the most part. The main issues the company has encountered had to do with the supply chain.

Other supply chain issues also came to light when Texas — a large distributor of raw materials — experienced its freeze in February 2021.

Hurricane Ian, in 2022, threw trees all over lines on which the raw materials move.

Nevertheless, the company finds a way to keep producing its product, King said.

Even inflation has been somewhat of a non-factor.

King said times are tough for everyone and he hopes the cost of living, locally, is addressed. Local governments are working to make things more affordable, he said, referencing meetings he has had with city staff such as North Port City Manager

Jerome Fletcher.

But despite prices surging for homes, groceries and other facets of everyday life, plastic is actually remaining quite consistent in its pricing, King said.

“We’re not causing inflation over here — most plastic has been its current price for quite a while,” King said.

YMCA-KING PARTNERSHIP

King hopes his facility’s new partnership with the YMCA of Southwest Florida can help employees who could benefit from its services.

A new YMCA location, which will be able to serve children from 6 weeks old to pre-K, is set to open soon right next to the King plant with funding help from the manufacturer.

Children of King employees are a priority, but the facility will also be open to the public.

It has been years in the making, King said.

The plan is something similar to what PGT Innovations did in Venice. That program started in 2018 and serves 90 children.

The North Port facility will be big enough for 150 children.

He believes it will be up and running in around a year, and will be an attractive benefit to potential employees.

“We hope it will attract talent we otherwise wouldn’t,” King said. “It might not be a big boom for us, but we’re happy it will be there to help. It is more of a need for the entire community though.”

YMCA studies indicate child centers are needed in North Port, especially following Hurricane Ian.

In the meantime, King and his team will continue what they have done quietly for decades, conducting and growing an international business from a quiet plant off of Toledo Blade Boulevard.

To learn more about King Plastic, visit kingplastic.com