KING PLASTIC TO SHOWCASE Its Popular Architectural Product Brands at IWF in Atlanta 2024

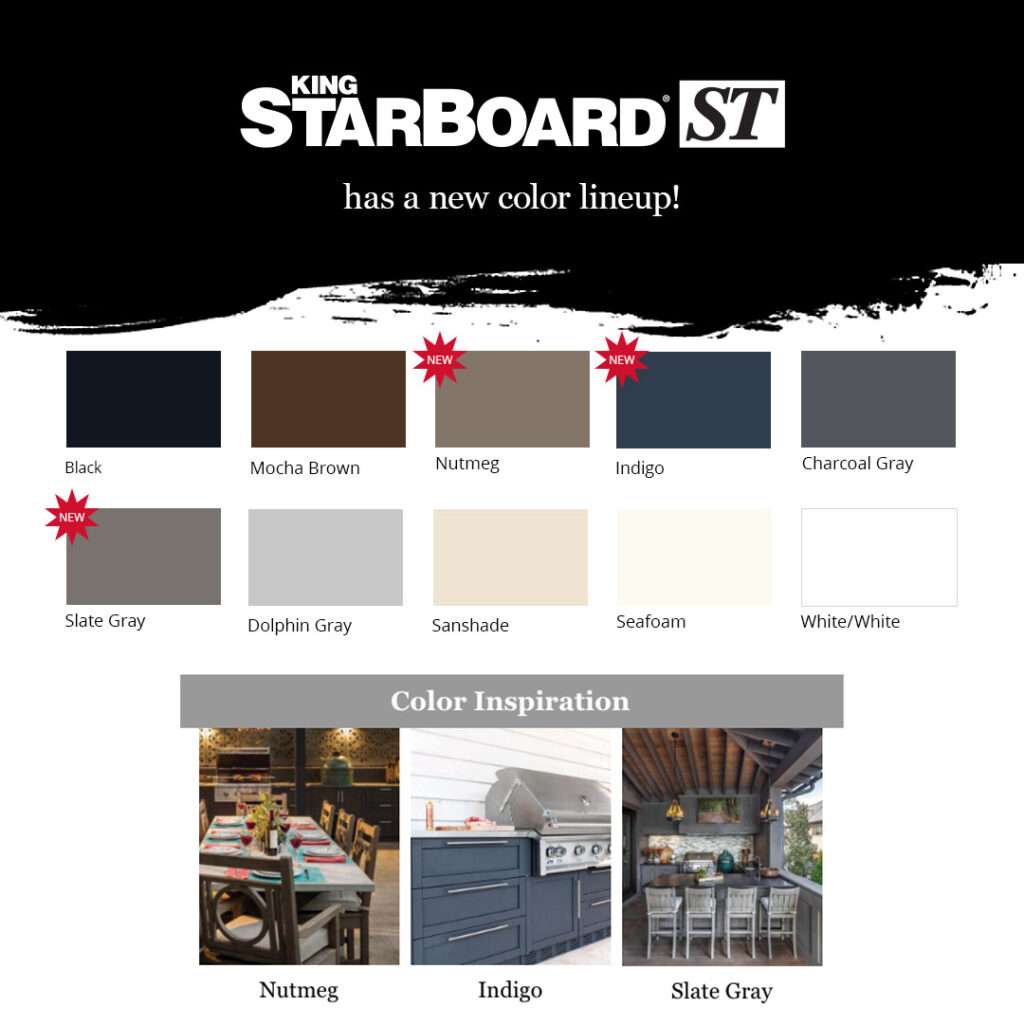

King Plastic Corporation, the leading manufacturer of polymer sheets, slabs, and massive shapes, will exhibit at the International Woodworking Fair (IWF) held August 6-9, 2024, in booth # C762, at the Georgia World Congress Center in Atlanta, GA. King Plastic will showcase its popular product brands: King StarBoard® ST, King StarBoard® WG and King DuraStyle®.

KING PLASTIC TO SHOWCASE Its Popular Architectural Product Brands at IWF in Atlanta 2024 Read More »