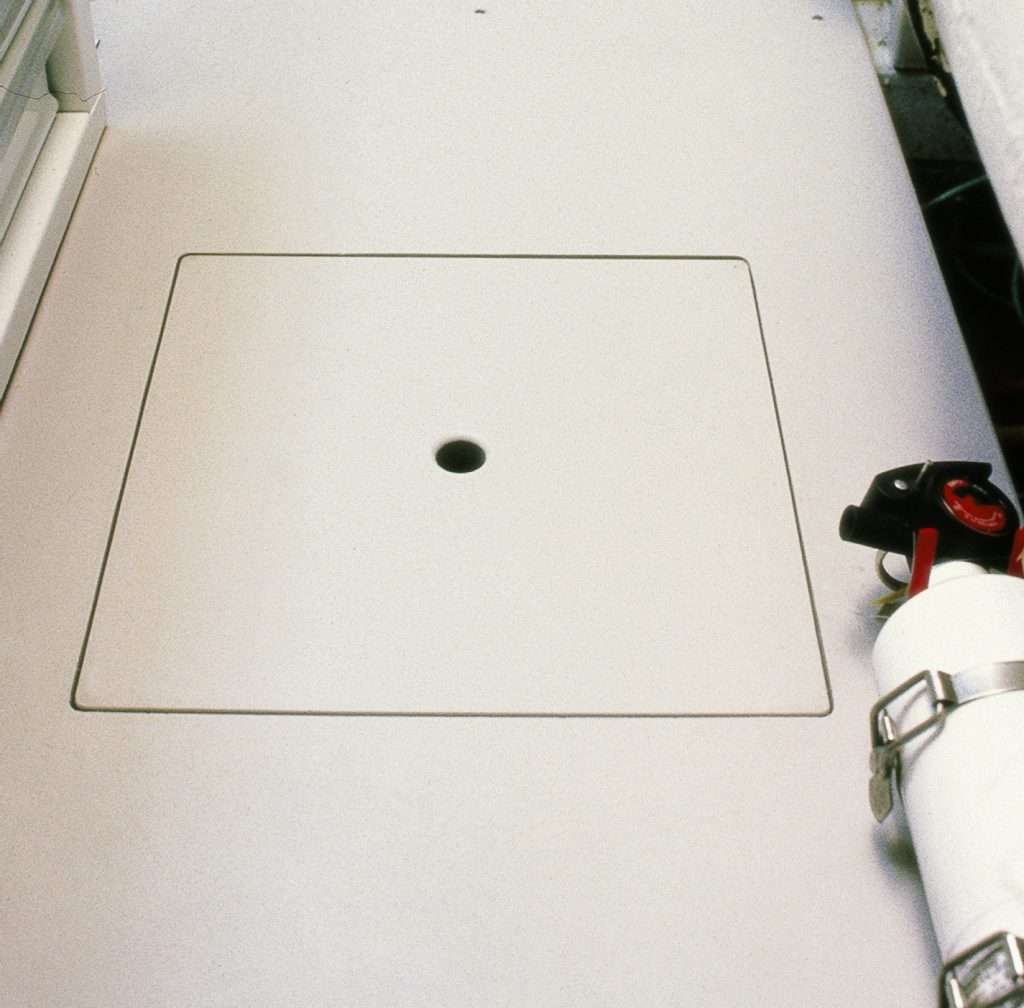

The Original Marine-Grade Polymer Sheet

King StarBoard®

Applications

- Bow Pulpits

- Countertops

- Frames and Trim

- Furniture

- Grab Rails and Handles

- Hatches and Doors

- Rod and Cup Holders

- Steps and Dock Boxes

- Tray Tables

Downloads

- King StarBoard® Literature

- King StarBoard® Industrial Literature

- Working With King StarBoard®

- King StarBoard® Care & Maintenance

- King StarBoard® Physical Properties

- Information Guide for Tools and Fabrication Techniques

- King StarBoard® SDS

- Chemical Resistance Chart

- Load Deflection Data

- Green LEED Information

- CNC Quick Fact Sheet

- General CNC Information

- King StarBoard® FAQ

- Expansion and Contraction Worksheet

Weight Calculator

Related Posts

[{"id":26805,"link":"https:\/\/www.kingplastic.com\/decorating-tips-to-transform-your-home-for-the-fall-season\/","name":"decorating-tips-to-transform-your-home-for-the-fall-season","thumbnail":{"url":"https:\/\/www.kingplastic.com\/wp-content\/uploads\/2023\/09\/Sept-2023-Blog-Post-Instagram-Post-min.png","alt":"Decorating Tips Featured"},"title":"DIY Decorating Tips to Transform Your Home for the Fall Season","postMeta":[],"author":{"name":"King Plastic","link":"https:\/\/www.kingplastic.com\/author\/mywebsite\/"},"date":"Sep 14, 2023","dateGMT":"2023-09-14 20:36:26","modifiedDate":"2023-10-25 09:56:44","modifiedDateGMT":"2023-10-25 13:56:44","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/www.kingplastic.com\/category\/news\/\" rel=\"category tag\">News<\/a>, <a href=\"https:\/\/www.kingplastic.com\/category\/king-starboard-family\/\" rel=\"category tag\">King StarBoard Family<\/a>, <a href=\"https:\/\/www.kingplastic.com\/category\/architectural-restrooms\/\" rel=\"category tag\">Architectural & Restrooms<\/a>","space":"<a href=\"https:\/\/www.kingplastic.com\/category\/news\/\" rel=\"category tag\">News<\/a> <a href=\"https:\/\/www.kingplastic.com\/category\/king-starboard-family\/\" rel=\"category tag\">King StarBoard Family<\/a> <a href=\"https:\/\/www.kingplastic.com\/category\/architectural-restrooms\/\" rel=\"category tag\">Architectural & Restrooms<\/a>"},"taxonomies":{"post_tag":"<a href='https:\/\/www.kingplastic.com\/tag\/news\/' rel='post_tag'>News<\/a><a href='https:\/\/www.kingplastic.com\/tag\/fall-season\/' rel='post_tag'>Fall Season<\/a><a href='https:\/\/www.kingplastic.com\/tag\/king-starboard\/' rel='post_tag'>King StarBoard<\/a>"},"readTime":{"min":1,"sec":13},"status":"publish","excerpt":"Whether you're looking for budget-friendly projects or craving a touch of elegance, there's something for everyone to enjoy. So, roll up your sleeves, gather your materials, and let your imagination run wild as you embark on autumn DIY projects. As the leaves change and the air turns crisp, these decorating tips will not only transform your home but also create lasting memories. Happy decorating!"},{"id":25602,"link":"https:\/\/www.kingplastic.com\/over-20-american-made-brands\/","name":"over-20-american-made-brands","thumbnail":{"url":"https:\/\/www.kingplastic.com\/wp-content\/uploads\/2023\/06\/Featured-Image-American-Made-Brands-min.png","alt":"American Made Brands"},"title":"Over 20 American-Made Brands","postMeta":[],"author":{"name":"King Plastic","link":"https:\/\/www.kingplastic.com\/author\/admin\/"},"date":"Jun 29, 2023","dateGMT":"2023-06-29 15:40:10","modifiedDate":"2024-09-27 06:56:17","modifiedDateGMT":"2024-09-27 10:56:17","commentCount":"0","commentStatus":"closed","categories":{"coma":"<a href=\"https:\/\/www.kingplastic.com\/category\/news\/\" rel=\"category tag\">News<\/a>, <a href=\"https:\/\/www.kingplastic.com\/category\/king-starboard-family\/\" rel=\"category tag\">King StarBoard Family<\/a>, <a href=\"https:\/\/www.kingplastic.com\/category\/king-colorcore\/\" rel=\"category tag\">King ColorCore<\/a>","space":"<a href=\"https:\/\/www.kingplastic.com\/category\/news\/\" rel=\"category tag\">News<\/a> <a href=\"https:\/\/www.kingplastic.com\/category\/king-starboard-family\/\" rel=\"category tag\">King StarBoard Family<\/a> <a href=\"https:\/\/www.kingplastic.com\/category\/king-colorcore\/\" rel=\"category tag\">King ColorCore<\/a>"},"taxonomies":{"post_tag":"<a href='https:\/\/www.kingplastic.com\/tag\/king-colorcore\/' rel='post_tag'>King ColorCore<\/a><a href='https:\/\/www.kingplastic.com\/tag\/summer\/' rel='post_tag'>Summer<\/a><a href='https:\/\/www.kingplastic.com\/tag\/aquariums\/' rel='post_tag'>Aquariums<\/a><a href='https:\/\/www.kingplastic.com\/tag\/zoos\/' rel='post_tag'>Zoos<\/a><a href='https:\/\/www.kingplastic.com\/tag\/king-starboard\/' rel='post_tag'>King StarBoard<\/a>"},"readTime":{"min":10,"sec":3},"status":"publish","excerpt":"As we celebrate Independence Day, we take great pride in being a manufacturing facility that produces American-made products. King Plastic Corporation, founded in 1968, stands as the leading manufacturer of high-quality polymer sheets, slabs, and massive shapes, many of which were pioneered by our company. Our headquarters is a spacious 250,000 square-foot manufacturing facility located in North Port, Florida, with an additional distribution facility in Medford, Oregon."}]