KING PLASTIC TO FEATURE ITS POPULAR PARKS AND RECREATION PRODUCT BRANDS AT 2023 NRPA ANNUAL CONFERENCE

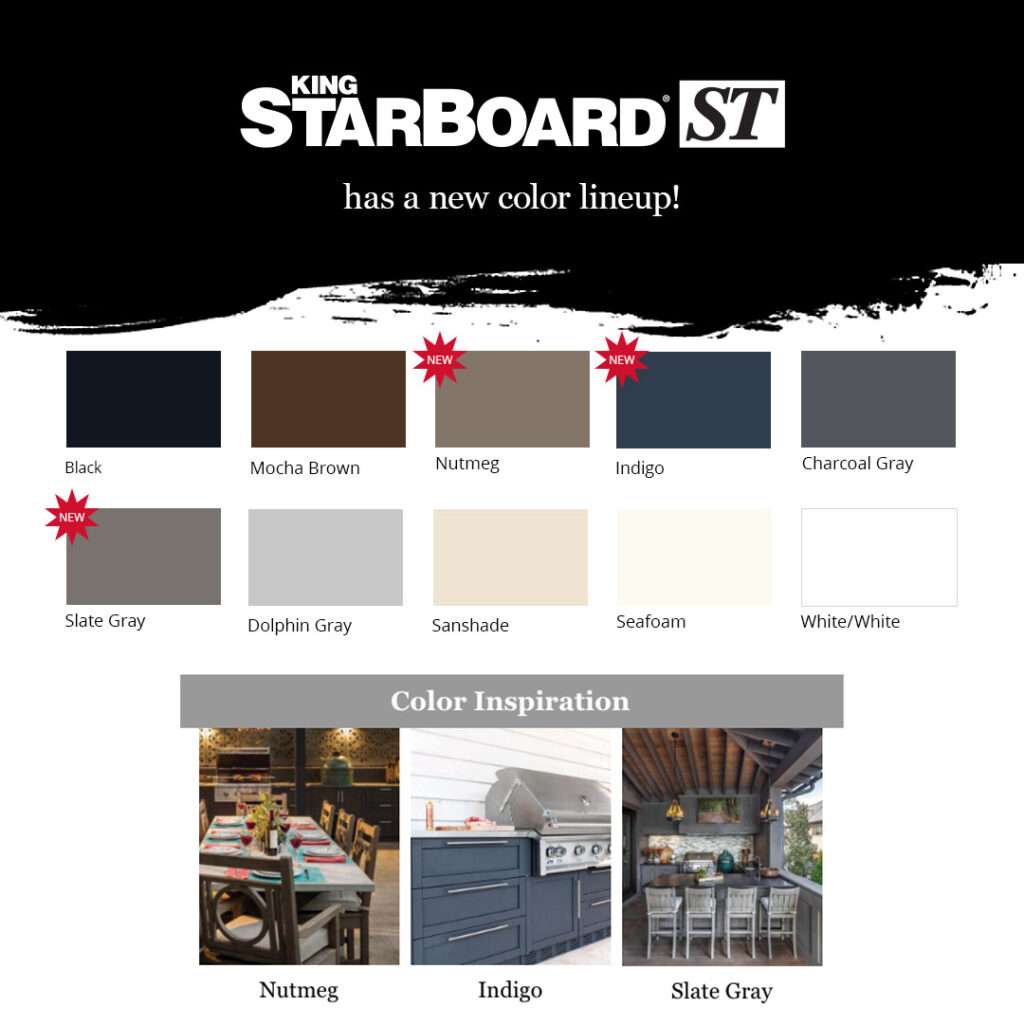

King Plastic Corporation will exhibit at the 2023 NRPA Annual Conference held October 10-12, 2023 at Kay Bailey Hutchison Convention Center in sunny Dallas, Texas. King Plastic Corporation will showcase its popular product brands King ColorBoard®, King ColorCore®, and King StarBoard® ST in booth # 1853.