4 Types of Wayfinding Signs

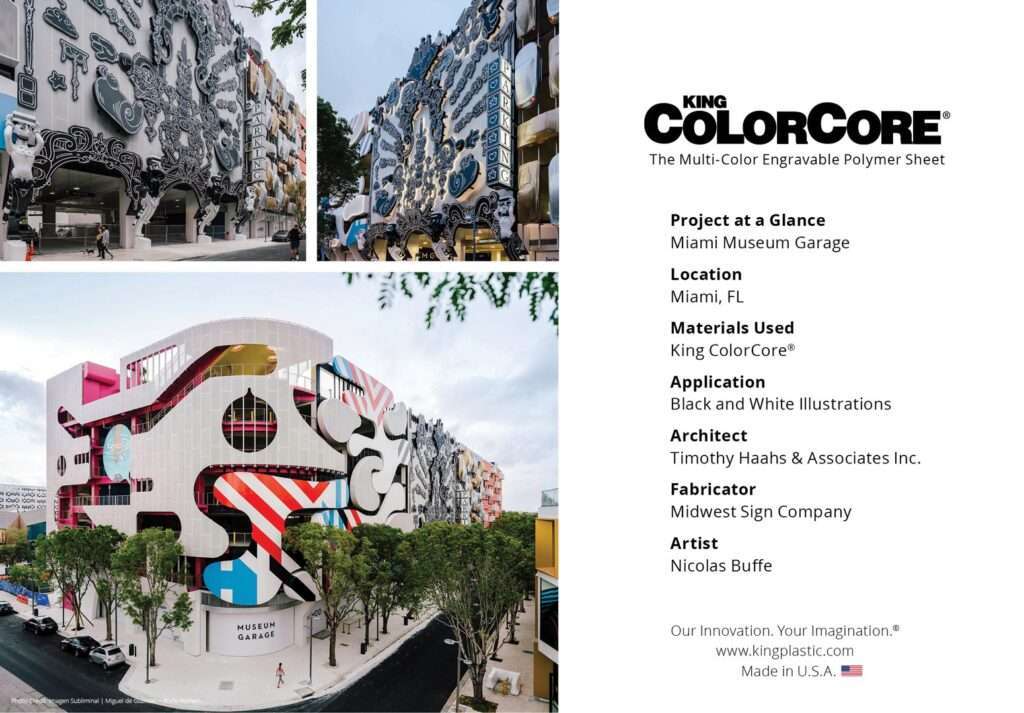

King ColorCore® is a popular HDPE material used for wayfinding signs because of its durability and versatility. Here are four examples of wayfinding signs made with King ColorCore® that can be used in different settings.

4 Types of Wayfinding Signs Read More »