What is King Plasti-Shield®?

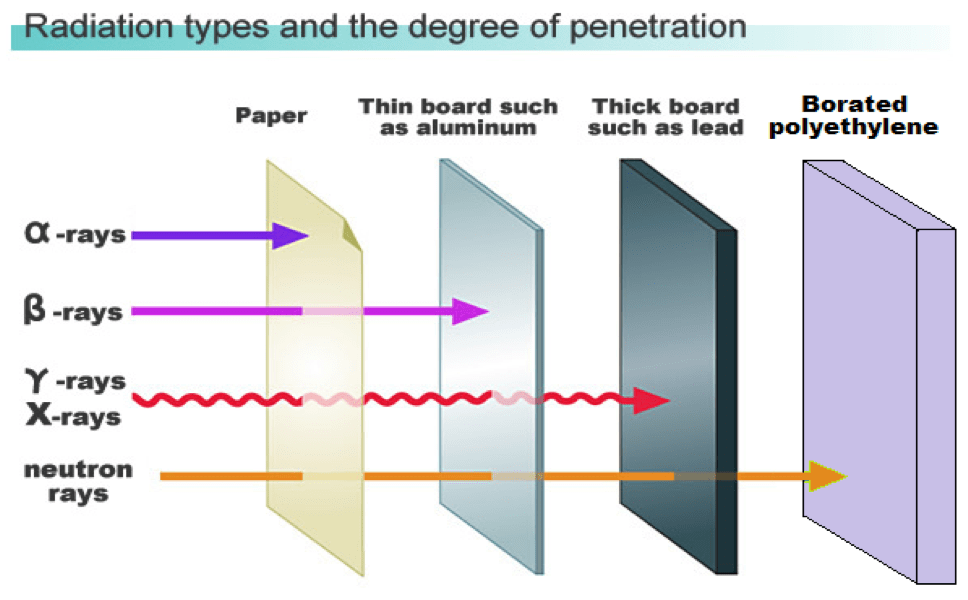

King Plasti-Shield® is a borated polyethylene neutron shielding material.

It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency of 1” thick. Custom sheets, blocks and slabs can be made as a special order in the compression mold or extrusion mold. King Plasti-Shield® has a smooth finish on both sides of the sheet.

It is made with 5% boron by weight and our trademark purple color. King Plasti-Shield® is an effective shielding material to meet all applicable applications for healthcare cancer treatment centers, diagnostic and hospital facilities. Applications include linear accelerators, nuclear or radiation shielding, industrial use, security such as seaports and airport security, nuclear submarines, nuclear power plants, border protection and other applications requiring attenuation of thermal neutrons. The polymer sheet never needs painting or refinishing, works like wood and it is easy to fabricate using common woodworking tools and techniques.

HOW IS IT USED?

king Plasti-Shield® is used to attenuate or absorb thermal neutrons.

These materials are commonly used in various industries and applications where protection against neutron radiation is required. Here are some key points regarding the use of neutron shielding materials:

What are the essential functions?

When specifying neutron shielding materials

Neutron Shielding material must do these things:

- Moderate or slow down neutrons: Neutron shielding materials facilitate the slowing down or moderation of fast-moving neutrons through scattering interactions with the atomic nuclei, increasing the chances of their absorption and reducing their potential for damage.

- Absorb slow neutrons: Neutron shielding materials incorporate elements with high neutron absorption cross-sections, such as boron or gadolinium, to readily capture slow or thermal neutrons, converting them into stable isotopes or non-harmful particles.

- Shield against any resulting radiation: Neutron shielding materials possess sufficient thickness and composition to attenuate and block the secondary radiation, such as gamma rays or secondary neutrons, produced when neutrons are absorbed, ensuring that the shielding effectively prevents their passage outside the shielded area.

- Minimize neutron scattering: Neutron shielding materials should effectively reduce the scattering of neutrons, preventing them from bouncing off and potentially causing secondary radiation hazards.

- Maintain structural integrity: Neutron shielding materials should possess sufficient structural strength and durability to withstand the operating conditions and potential impacts, ensuring long-term effectiveness of the shielding.

- Consider weight and space constraints: Neutron shielding materials should be designed to provide optimal shielding efficiency while considering limitations in weight and space, especially in applications like transportation or portable radiation shielding devices.

WHERE Is neutron shielding used?

king Plasti-Shield® neutron shielding material applications are used in various industries and settings where protection against neutron radiation is required.

Some common areas where borated polyethylene neutron shielding is used include:

- Nuclear Power Plants: Borated polyethylene is used extensively in nuclear power plants to shield personnel and sensitive equipment from neutron radiation. It is employed in reactor containment structures, control rooms, and areas with high neutron flux, such as spent fuel pools.

- Research Reactors: Research facilities and laboratories housing nuclear reactors utilize borated polyethylene shielding to protect scientists, researchers, and instrumentation from neutron radiation. It is used in beamlines, experimental areas, and control areas to ensure safety during reactor operation.

- Medical Facilities: Borated polyethylene is employed in medical facilities where neutron-producing equipment is used, such as linear accelerators for radiation therapy. It helps shield patients, medical personnel, and bystanders from neutron radiation during treatments.

- Industrial Radiography: In industrial applications like radiography, where neutron sources are used to inspect materials, borated polyethylene is utilized to create shielding barriers. It safeguards workers and prevents unnecessary exposure to neutron radiation.

- Research and Education: Borated polyethylene is utilized in research and educational institutions conducting neutron-based experiments, such as neutron scattering studies or nuclear physics research. It provides shielding to researchers, students, and equipment in these facilities.

- Transportation of Radioactive Materials: Borated polyethylene is sometimes used in transport casks or containers for the safe transportation of radioactive materials, including isotopes that emit neutrons. It acts as a shielding material to minimize neutron radiation exposure during transit.

- Defense and Homeland Security: Borated polyethylene can be employed in defense and homeland security applications to protect personnel and critical infrastructure from potential neutron sources, such as nuclear materials or devices.