The Original Marine-Grade Polymer Sheet

Applications

- Bow Pulpits

- Countertops

- Frames and Trim

- Furniture

- Grab Rails and Handles

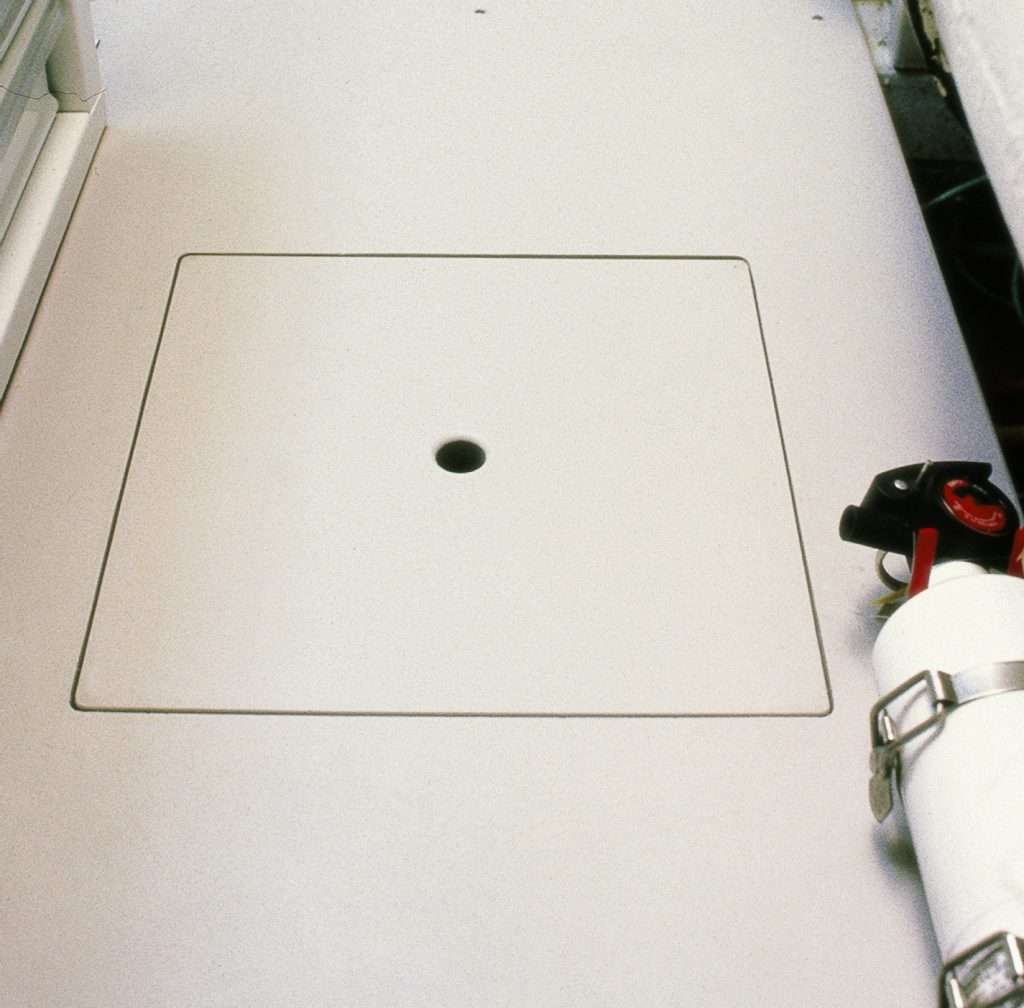

- Hatches and Doors

- Rod and Cup Holders

- Steps and Dock Boxes

- Tray Tables

King StarBoard® is the original marine-grade high-density polyethylene sheet and the leading brand in the marine industry. The King name is synonymous with quality to those who know plastics, and the King StarBoard® brand has been helping pros build better boats for more than thirty-years. It is the product of a proprietary process called K-Stran™, the most advanced manufacturing process for superior flatness and consistency. King StarBoard® has a matte finish on both sides of the sheet. It is environmentally stabilized to withstand the harshest outdoor conditions. King StarBoard® will not rust, delaminate or rot when exposed to UV, humidity or water. It is ideal for a variety of marine applications from replacing wood, to building boat components and furniture. The polymer sheet never needs painting or refinishing, works like wood, and is easy to fabricate with common woodworking tools and techniques.

King StarBoard® is upgradable to King MicroShield® with an advanced antimicrobial technology for protecting the product surface against stain and odor causing bacteria, algae and fungi.*

King StarBoard® is upgradable with King FlameShield, for ASTM E-84 Class A Flame Compliance and CAN/ULC-S102 for Canadian Compliance.

For more information about King MicroShield® and King FlameShield, please visit those product pages.

Disclaimer: King MicroShield® may affect color. King FlameShield may affect finish and color.

*For bacteriostatic, fungistatic, & algistatic properties. This product is exempt from registration under 40 CFR 152.25(a). King MicroShield® effectiveness verified by ISO and ASTM standards. This product does not protect users or others from disease-causing bacteria. Always clean this product thoroughly after use.

Standard Sheet Sizes

| in: | 48” x 96” | 54” x 96” |

| mm: | 1219mm x 2438mm | 1371.6mm x 2438mm |

| Colors | Only in 1-1/2” gauge, all standard colors available 1/4″ up to 1″ gauges available in black or white | All standard colors available |

Standard Gauges

| in: | 1/4” | 3/8” | 1/2” | 3/4” | 1” | 1-1/2” |

| mm: | 6.4mm | 9.53mm | 12.7mm | 19mm | 25.4mm | 38mm |

Approximate Weight 48 x 96 (only in 1-1/2″ gauge)

| lbs: | 40 lbs | 60 lbs | 80 lbs | 120 lbs | 160 lbs | 240 lbs |

| kg: | 18.14 kg | 27.2 kg | 36.3 kg | 54.4 kg | 72.5 kg | 108.8 kg |

Approximate Weight 54 x 96

| lbs: | 45 lbs | 67.5 lbs | 90 lbs | 135 lbs | 180 lbs |

| kg: | 20.4 kg | 30.6 kg | 40.8 kg | 61.2 kg | 81.6 kg |

Tolerance information:

Gauges 1/4″ up to 1-1/2” ± 5% | Length and width plus only at room temperature

Custom sheet sizes, gauges and colors available

| Properties | Units | ASTM | Nominal Values |

| Density | g/cc | D1505 | 0.955 |

| Tensile Strength @ Yield | psi | D638 | >4,100 |

| Tensile Modulus | psi | D638 | 255,000 |

| Elongation @ Break | % | D638 | >600 |

| Elongation @ Yield | % | D638 | 9.8 |

| Flexural Modulus | psi | D790 | 185,000 |

| Flexural Stress @ 5% Strain | psi | D790 | 3,810 |

| Compressive Properties 10% Strain | psi | D695 | 4,950 |

| Durometer | Shore D | D2240 | 68 |

| Tensile Impact | ft.lbs./in.2 | D1822 | 115 |

| Izod Impact Resistance | ft.lbs./in.2 | D256 | 1.1 |

| Brittleness Temp. | ºC (ºF) | D746 | <-76ºC (<-105ºF) |

| Vicat Softening Temp. | ºC (ºF) | D1525 | 123ºC (253ºF) |

| Heat Deflection Temp. 66 psi | ºC (ºF) | D648 | 75ºC (167ºF) |

| Screw and Nail Withdrawal | lbs | D1761 | 657 & 63 |

| Flammability | Rating | UL94 | HB |

All values are determined on specimens prepared according to ASTM standards.

Nominal values should not be interpreted as specifications.

King StarBoard® is made entirely from FDA and USDA approved material.

King StarBoard® meets ASTM D4976.

The raw material used to make King StarBoard® does not contain BPA’s or Phthalates.

- Made of the finest polymers available, using our proprietary K-Stran™ process for superior flatness and consistency.

- Environmentally stabilized for harsh sun and tough marine environments.

- Will not rot, swell, splinter or delaminate when exposed to humidity or water.

- Precise tolerances ensure consistent color, thickness and density, even for special thickness gauges and custom

order colors. - Easy to fabricate with standard woodworking tools and requires little or no finishing.

- Available in eight standard colors to match or accent any gelcoat.

- Unlimited custom/proprietary colors.

- Durable matte-textured surface on both sides.

- Easy to clean and never needs refinishing.

- Edges finish cleanly and easily.

- Forms easily for smooth curves.

- Has passed the Federal Motor Vehicle Standard 302 fire test required for use in motor vehicles, including motor homes.

- Available in large sheets up to 54” x 96” or 48” x 96”.

- Custom sheet sizes available.

- Shipped with a protective masking on one side.

- Proven on thousands of boats and yachts.

- Experienced boat builders and boaters know the King StarBoard® brand and trust it more than any other.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Downloads

- King StarBoard® Literature

- Working With King StarBoard®

- King StarBoard® Care & Maintenance

- King StarBoard® Physical Properties

- Information Guide for Tools and Fabrication Techniques

- King StarBoard® SDS

- Chemical Resistance Chart

- Load Deflection Data

- Green LEED Information

- CNC Quick Fact Sheet

- General CNC Information

- King StarBoard® FAQ

- Expansion and Contraction Worksheet