The Multi-Color Engravable Polymer Sheet

Applications

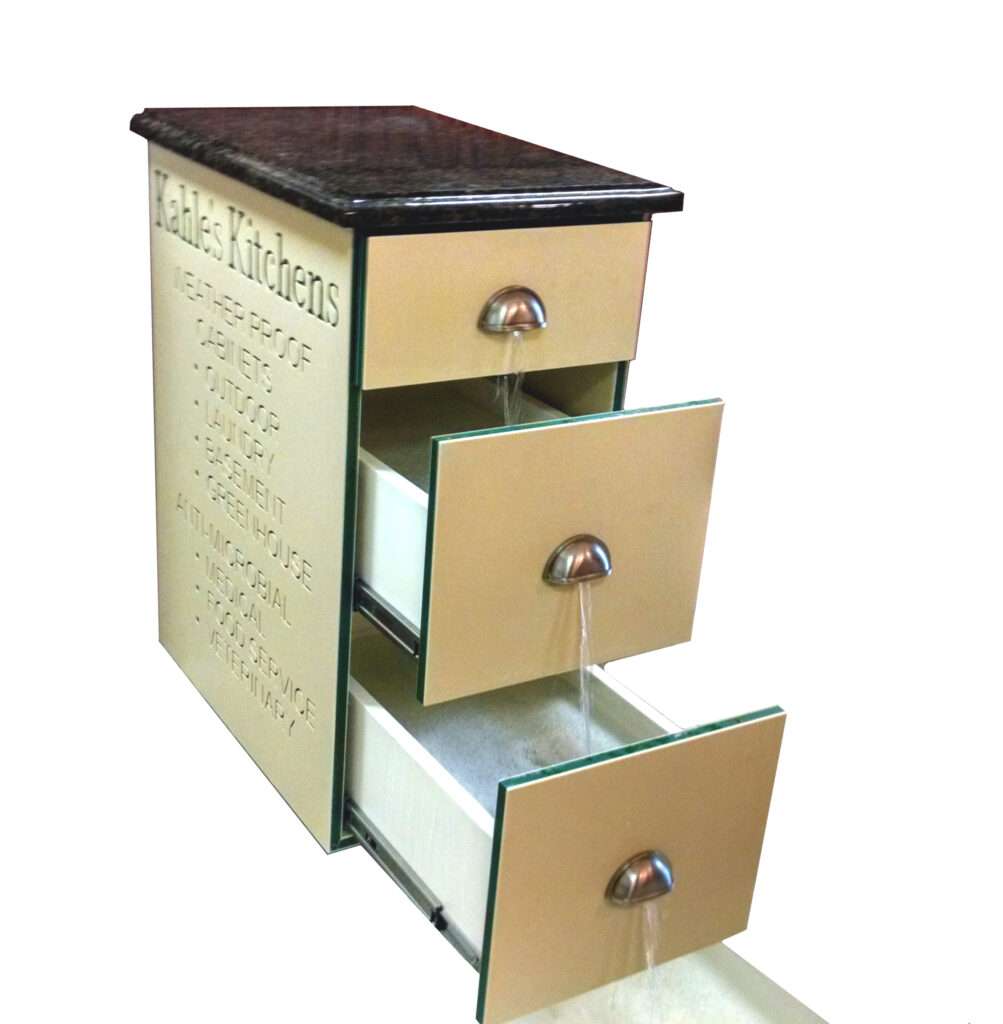

- Architectural Applications

- Carnival Games

- Children’s Furniture

- Marine Applications

- Museums

- Picnic Tables

- Point-of-Purchase Displays

- Signage and Wayfinding

King ColorCore® is a versatile multi-color engravable high-density polyethylene sheet with multiple layers of contrasting colors. It is a superior homogeneous sheet, a product of a unique state-of-the-art continuous process called Polyfusion, and manufactured to the highest standards in the industry. King ColorCore® has a matte finish on both sides of the sheet. It is environmentally stabilized to withstand the harshest outdoor conditions. King ColorCore® will not rust, delaminate or rot when exposed to UV, humidity or water. King ColorCore® is made with high-impact-resistant polymer to handle more abuse than conventional sign materials. Its thin cap layers and bright primary colors make it ideal for signage, marine, playground and recreational applications. For maximum versatility, standard colors are made to coordinate with King ColorBoard®. The polymer sheet never needs painting or refinishing, works like wood and it is easy to fabricate using common woodworking tools and techniques. The material is easy to engrave and machine, as the cap is approximately .050” thick.

King ColorCore® is upgradable to King MicroShield® with an advanced antimicrobial technology for protecting the product surface against stain and odor causing bacteria, algae and fungi.*

For more information about King MicroShield®, please visit the product pages.

Disclaimer: King MicroShield® may affect color.

*For bacteriostatic, fungistatic, & algistatic properties. This product is exempt from registration under 40 CFR 152.25(a). King MicroShield® effectiveness verified by ISO and ASTM standards. This product does not protect users or others from disease-causing bacteria. Always clean this product thoroughly after use.

Standard Sheet Size

| in: | 48″ x 96″ |

| mm: | 1219mm x 2438mm |

Standard Gauges

| in: | 1/4″ | 1/2″ | 3/4″ |

| mm: | 6.4mm | 12.7mm | 19mm |

Approximate Weight

| lbs: | 40 lbs | 80 lbs | 120 lbs |

| kg: | 18.14kg | 36.3kg | 54.4kg |

Cap thickness is .050″ for both sides of the material.

Tolerance information:

Gauges 1/4″ up to 3/4” ± 5% | Length and width plus only at room temperature

Custom sheet sizes, gauges and colors available

| Properties | Units | ASTM | Nominal Values |

| Density | g/cc | D1505 | 0.955 |

| Tensile Strength @ Yield | psi | D638 | >4,100 |

| Tensile Modulus | psi | D638 | 255,000 |

| Elongation @ Break | % | D638 | >600 |

| Elongation @ Yield | % | D638 | 9.8 |

| Flexural Modulus | psi | D790 | 185,000 |

| Flexural Stress @ 5% Strain | psi | D790 | 3,810 |

| Compressive Properties 10% Strain | psi | D695 | 4,950 |

| Durometer | Shore D | D2240 | 68 |

| Tensile Impact | ft.lbs./in.2 | D1822 | 115 |

| Izod Impact Resistance | ft.lbs./in.2 | D256 | 1.1 |

| Brittleness Temp. | ºC (ºF) | D746 | <-76ºC (<-105ºF) |

| Vicat Softening Temp. | ºC (ºF) | D1525 | 128°C (262°F) |

| Heat Deflection Temp. 66 psi | ºC (ºF) | D648 | 99°C (210°F) |

| Screw and Nail Withdrawal | lbs | D1761 | 657 & 63 |

| Flammability | Rating | UL94 | HB |

All values are determined on specimens prepared according to ASTM standards.

Nominal values should not be interpreted as specifications.

King ColorCore® is made entirely from FDA and USDA approved material.

King ColorCore® meets ASTM D4976.

The raw material used to make King ColorCore® does not contain BPA’s or Phthalates.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Downloads

- King ColorCore® Literature

- King ColorCore® Care & Maintenance

- King ColorCore® Physical Properties

- King ColorCore® SDS

- Chemical Resistance Chart

- Green LEED Information

- Quick CNC Fact Sheet

- CNC Engraving King ColorCore

- Information Guide for Tools and Fabrication Techniques

- King ColorCore® FAQ

- Expansion and Contraction Worksheet