SNEAK PEAK AT WHAT’S NEW

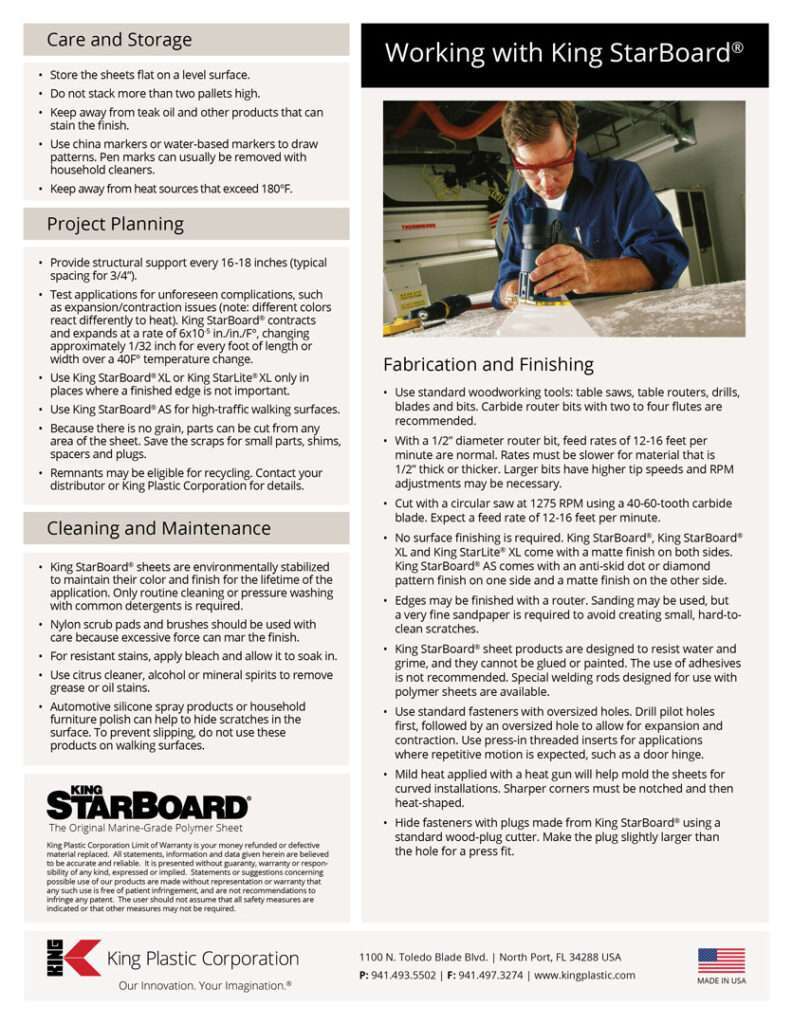

Here is a sneak peek at what’s new! King Plastic Corporation, the leading manufacturer of polymer sheets, slabs and massive shapes, introduces its new King StarBoard™ WG product brand, the all-weather wood grain polymer sheet inspiring everyone to live outdoors. King Plastic Corporation is adding two new colors to the lineup for King StarBoard® ST […]

SNEAK PEAK AT WHAT’S NEW Read More »